Capital Aerospace Company Six-axis Robot Automatic Shot Peening Machine

Capital Aerospace Machinery Corporation, Chinas largest launch vehicle assembly and integration enterprise and a leading aerospace high-tech manufacturing base, specializes in modern rocket manufacturing. In 2024, Disa designed, installed, and commissioned a six-axis robotic automated shot blasting chamber for the company.

Fully automated shot blasting equipment primarily utilizes robots or mechanical arms for blasting operations. It enables automated processing of large components, flexibly adapting to workpieces of varying sizes and shapes, and efficiently cleaning complex, oversized parts.

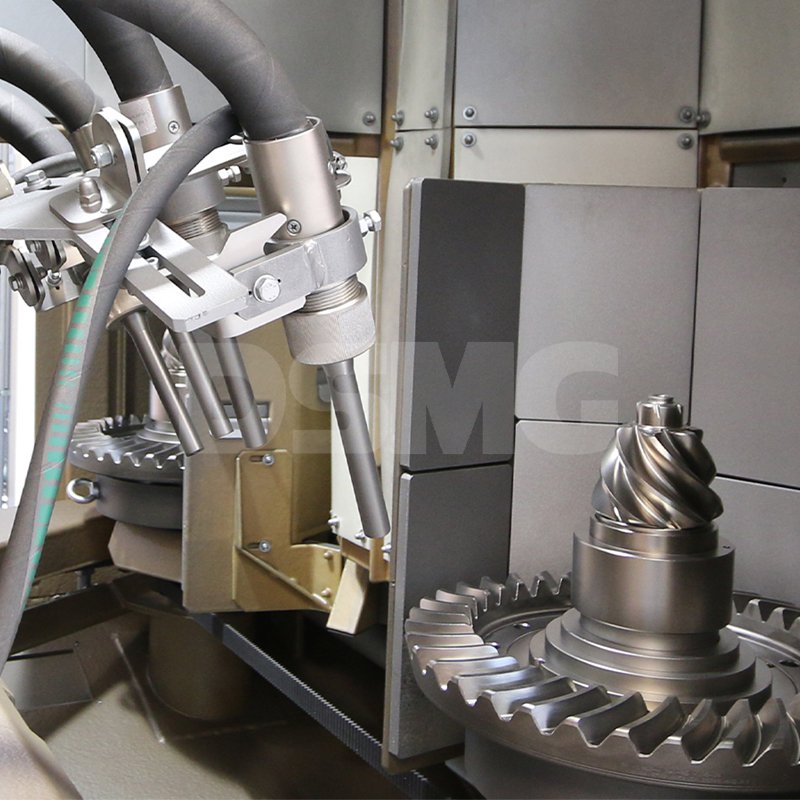

Nozzle-mounted robotic arms inside the blasting chamber perform automated surface blasting. The robotic arm directs nozzles to target intricate or concealed areas, eliminating blind spots and accelerating the cleaning process. The robot can manually strengthen individual workpieces or fully automate batch processing.

It accommodates any size or shape of abrasive media based on surface requirements.

Programming is executed via joystick control by operators, enabling automated blasting of similar workpieces using preconfigured programs.

This system eliminates traditional blasting room challenges such as manual labor, high intensity, and safety risks.

For serial workpiece processing:

The blasting chamber integrates a robotic unit for faster and more efficient handling.

Custom design services ensure alignment with clients’ specialized requirements. Multi-hopper blasting chambers are suitable for use with metal abrasives (structural steel, alloys, stainless steel) in magnetic separation blast rooms or non-metallic applications.

中文版

中文版