Preventive Maintenance

Long-term machine performance can be directly linked to preventive maintenance and parts service. Routine inspections and proper maintenance are the fundamental necessities towards keeping your blast equipment running efficiently. Our service technicians are not only capable of conducting an on-site inspection, but can also help our customers create a maintenance schedule based on specific operating conditions.

Operator knowledge

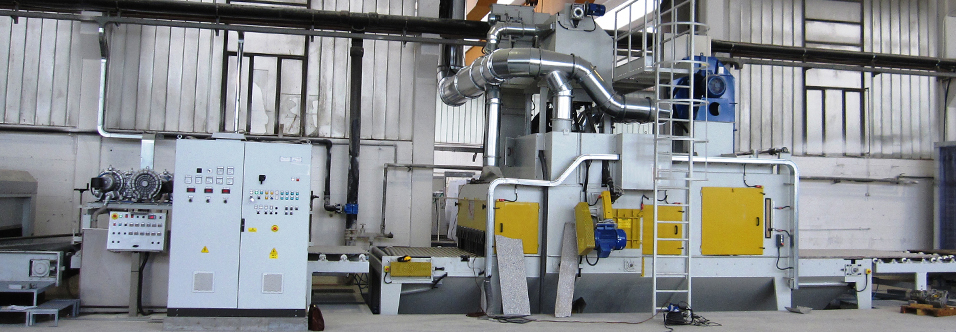

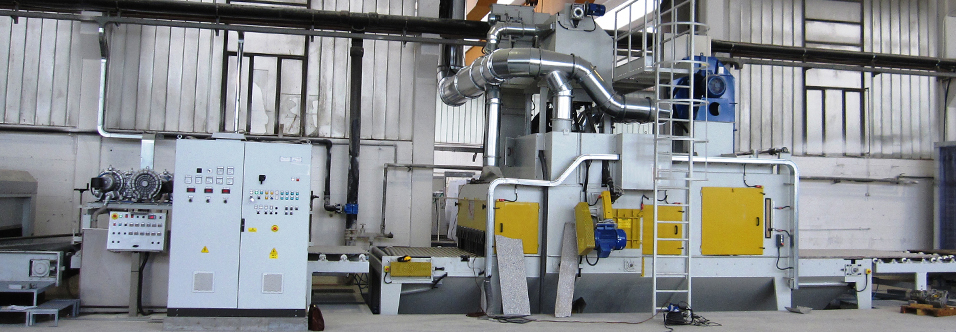

Not only the correct operation of the machines is important. It is also critical to assure proper maintenance. Disa educates its customers during training and via manuals on how to conduct essential maintenance. New operators learn the basics of maintenance the first time they start using the machines.Ease of maintenance is critical for blasting machines which require additional maintenance than more traditional structural machinery. The Disa was designed with maintenance in mind. With the purpose to blast away profile imperfections, such as rust and scale, the machine needs easy access for maintenance purposes.

Periodic check-ups

Disa recommends periodic preventive maintenance check-ups by experienced Disa engineers. These check-ups are conducted based on knowledge, experience and measurements. The maintenance module in the Customer Services contract enables customers to let Disa take care of the planning of these check-ups. This way our customers can focus on their core business.