Automatic steel pipe shot blasting machine is adopted to remove the surface rust and high-speed projectile flow that is blasted through the efficient blast wheels is adopted to crush scale, rusty layer and other things on the surface inside the steel pipe, so that the tensile strength and compression strength of the workpiece are enhanced, the adhesion is added for the paint protection of the inner surface and the purposes of anticorrosion, pipe protection and prolonged service life of the steel pipe are achieved. The gloss finish and roughness of the surface after blasting reach the relevant standard requirements.

Working principal of the steel pipe shot blasting machine: the machine is a roller conveyor shot blasting machine. The steel pipe is placed on the feeding conveying roller and the installation position and conveying speed of the riding wheels are set according to different pipe diameter. The installation angle of the riding wheels can be adjusted to make the steep pipe rotate and go forward. The steel pipe entering the blasting area of the blasting chamber is subjected to being attacked and rubbed by the intensive abrasives that are thrown out by the two powerful and efficient blast wheels mounted on the bottom of steel pipe inner wall shot blasting machine, in order to make the scale, rusty layer and other things on the surface be quickly fallen off and make the surface obtain a gloss finish with a certain roughness and show the metal color. During shot blasting, the fallen-off abrasive and dust go through the chamber body hopper and the lower chute and accumulated on the lower of the elevator, then elevated to the separator on the upper of the machine. The separated clean abrasives fall into the hopper of the separator for abrasive cycle use. The dust produced during shot blasting is conveyed to the dust collecting system through the exhaust pipe. After the dust is processed by the dust collecting system, the granular dust is captured and collected and the purified air is discharged to the atmosphere. After the steel pipe is processed, the steel pipe is conveyed out of the blasting chamber and go into the unloading end of the conveyor roller.

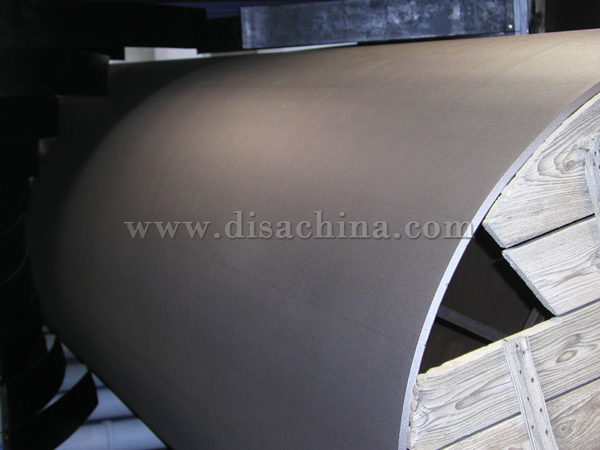

chamber with protection has a closed metal construction covered inside with rubber sheets to absorb cinematic shot energy. The pipes are directed in translation and rotation motions, one after another, by a transport device into the shot blasting chamber where they are cleaned.

The steel pipe shot blasting machine is specifically designed as a continuous process to shot blast the external of pipes with 6mm diameter to 3000mm diameter.

The blast wheels are mounted under the pipe therefore maintaining the distance from the blast wheel to the surface of the pipe allowing a large range of pipe sizes to be efficiently cleaned with minimal adjustments.

Rubber seals are provided on both the inlet and outlet sides of the machine that are changed to suit the pipe size to minimize the escape of abrasive from the machine. The conveyors are with variable pitch. They consist of directly driven rubber tires that are moved in or out to suit the diameter of the pipe. The tires are angled and the speed controlled by a frequency controller to give the required through put speed. The adjustment can be done manually or hydraulic as an option control.

Advantage:

1)The fixed sealing chamber is a steel plate and structural steel welding structure and has strength and rigidity. The shape and size of the chamber body and installation location and direction of the blast wheels are determined through CAD optimization and dynamic simulation, so that the blasting effect is well guaranteed, and the efficiency of the machine is maximized. The port blasting area of the steel pipe is protected through ZGMn13 plate and it is good in wear-resisting property and durable. The fixing nuts of the protective plate is casted through ZGMn1. The undersurface of the chamber body is provided with gratings and the main blasting area on the upper of the gratings is provided with special perforated wear-resisting plates to prevent the abrasives to destroy the gratings, hopper and lower spiral conveyor. The remaining parts are protected by the rubber plate and the protective plates are convenient to assemble, disassemble and replace. The inlet and outlet of the steel pipe are provided with rubber sealing curtain and can effectively prevent the steel grits to fly out. The fixed sealing chamber is connected with the 22kw fan on the dust collector. The pneumatic conveying of the abrasives and the accumulation and settling of the abrasives in the fixed sealing chamber are realized through the special structure of the sealing chamber.

2) Impeller head is located at multi angle, which is the high efficiency blasting wheels, shot blasting with high-speed thick blasting pills and blowing on the surface to have a tridimensional and omnibearing cleaning,

3) To clean away the rusting layer, oxidation layer and other dirty things from surface quickly,

4) To make surface achieve a bright and clean surface and to improve the adhesion force of painting to surface and improve the anti-fatigue force and anti-rust capacity of surface,

5) Improve the inherent quality of surface and prolong the lifetime of steel pipe or tube.

This steel pipe shot blasting machine for external surface of pipe is widely used in the industries of petroleum, chemical, steel, city group heating and group drainage ect.