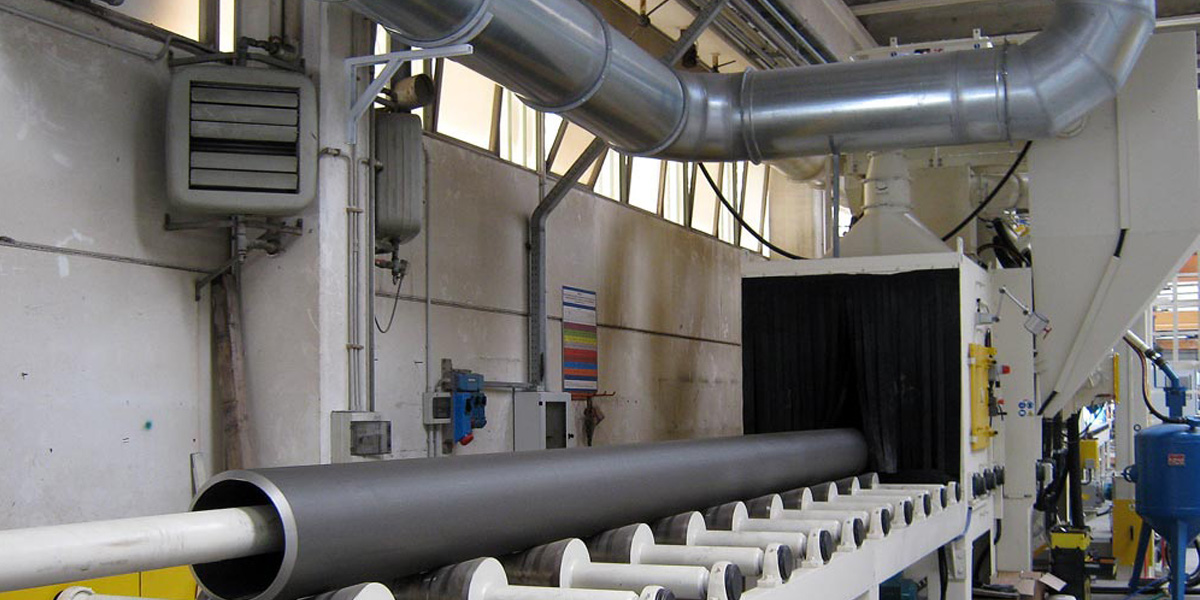

When the steel pipes pass through the shot blasting unit of the Disa steel pipe shot blasting machine, it drives the steel pipes to rotate, enabling the entire surface of the outer diameter of the steel pipes to be exposed to the shot blasting flow. This model can handle steel pipes with a maximum diameter of up to 3 meters, and the current model is suitable for the conventional pipe diameter range (150 mm to 1,200 mm).

Working Principle of the Steel Pipe Shot Blasting Equipment:

Loading Stage

The materials to be shot blasted are safely placed on the conveyor belt.

The conveying speed of the materials entering and exiting the equipment is precisely controlled through the speed regulation system (the speed adjustment is executed by a dedicated control unit).

Shot Blasting Execution

With the help of the high-pressure turbine units installed at the top and bottom of the main cavity, the materials can achieve single-time shot blasting full coverage treatment without the need for turning.

Abrasive Recycling

The built-in bucket elevator of the equipment conveys the steel shots to the separator.

After the dusty steel shots are filtered for dust through the screen of the separator, the clean steel shots are reinjected into the turbine system for recycling.

Dust Removal System

An efficient filter bag dust removal unit is adopted, and the fabric filter bags have excellent dust collection capabilities.

After the shot blasting is completed, the cleaned workpieces are safely output from the conveyor belt, getting ready for the downstream processes.

Pipe Diameter Adaptability Technology

The shot blasting wheel set is installed below the steel pipe, accurately maintaining the distance between the shot blasting wheel and the pipe wall to achieve compatibility with a wide range of pipe diameters (minimizing the cost of machine adjustment).

The inlet and outlet of the equipment are equipped with replaceable rubber seals, and the sealing specifications are matched according to the pipe diameter size to minimize the spillage of abrasives.

Conveyor Belt System

A variable pitch Diablo conveyor belt is used, and its direct-drive rubber tires can radially expand and contract to adapt to different pipe diameters.

The tire inclination angle and linear speed are adjusted by a variable frequency controller to ensure that the conveying speed is precisely controllable, and it supports manual or optional hydraulic control.

The current model of the conveyor belt has a load-bearing strength of up to 750 kilograms per meter, and higher specifications are available.

Overall Configuration

It is standardly equipped with a fully automatic abrasive recovery and regeneration system and a dust removal device.

The operation of the equipment is centrally controlled by a PLC system, integrating a full-link safety interlock protection mechanism.

中文版

中文版