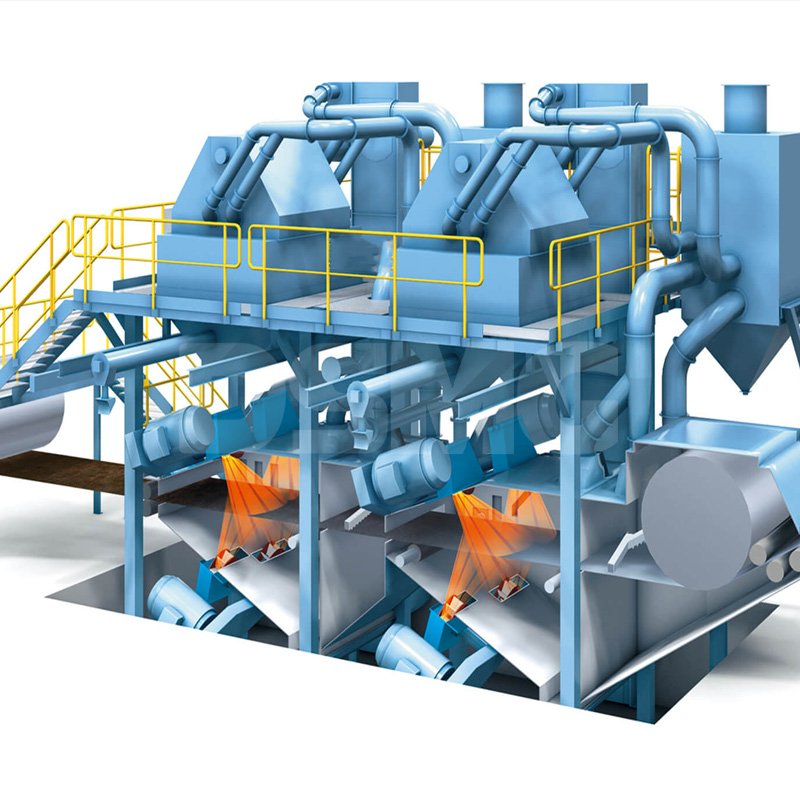

The steel strip shot blasting machine consist of multiple centrifugal blast wheels each of them driven by individual motors to give a through cleaning. The jobs kept on suitable conveying system with variable speed flexibility. The jobs enter the blast cabinet for cleaning from abrasives fired by multi wheels for homogeneous finish. The duly shot blasted components come out from the exit of cabinet. These machine's are fully equipped with abrasive recovery and cleaning system, dust collector, control panel and manganese lining.

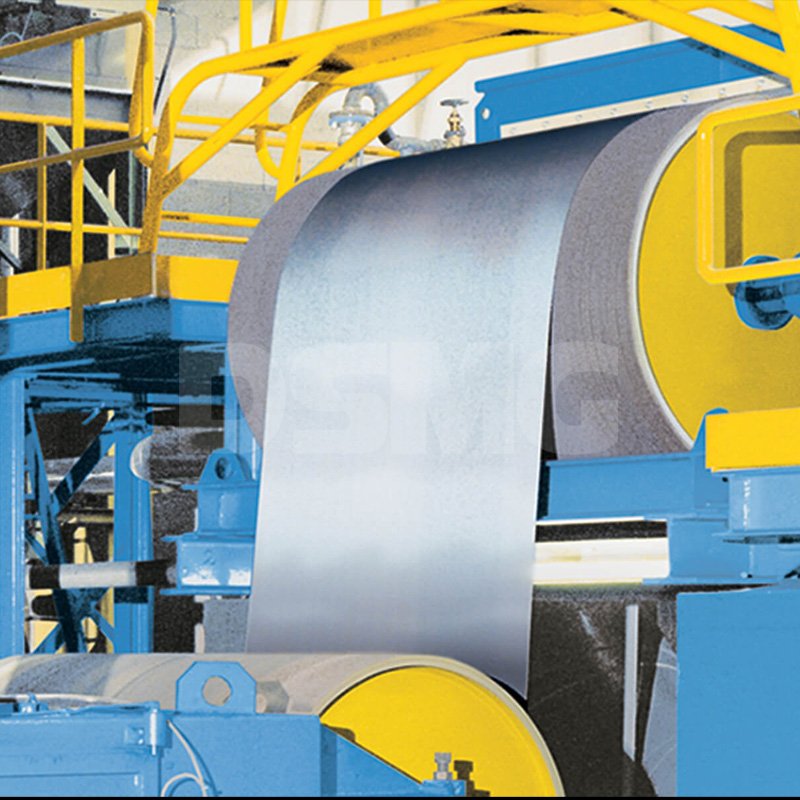

The Strip Shot Blasting Machine are used for de-scaling of carbon steels, stainless steels ranging from 350 to 1800 mm width, shot blasting speed : 2 meter to 60 meter/min or more. Eliminates pickling, surface is completely free of scale, Strip Shot Blasting Machine can be installed in individual or inline process. Operation is simple require minimum labor.

The strip is fed from de-coiler to inward side of tunnel /vestibule of pinch rollers of shot blasting machine. Then the strip enters into blasting chamber for blasting operation/purpose.8 blast wheel stations are located strategically on to blasting cabinet.(4 wheels are located on top of blasting cabinet and 4 wheels are located on to bottom portion of blasting cabinet) .the blasted /cleaned strip moves forward and enter into out let tunnel/ vestibule. From there strip is pulled by coiler and other equipment (arranged by customer).The machine is designed for cleaning strip 60m per minutes.

The Blast Cabinet is fabricated from 12mm thick heavy-duty prime quality steel plates, supported by strong rolled structure welded construction and engineered suitably for strength and rigidity to guarantee the optimum sturdiness. This robust rolled structure with thick plate foundation holds stand the machine and helps to reduce vibration keep within permissible limits. The Blast cabinet bottom is provided with mild steel perforated floor for protection against abrasion wear. The Vestibules are fabricated with 6mm thick sheet. The entire cabinet is lined with 10mm MnS.

The machine entails robust and sturdy Blast Cabinet on which 8 Blast Wheel Station are located at de-scaling angle. The cabinet is also equipped with Abrasive Recovery & Cleaning System and Dust Collector for ventilating Blast Cabinet. The strip is fed from de coiler to inward side of tunnel through pinch roller of Shot Blasting Machine. The strips enters into Blasting Chamber for Blast cleaning application. 8 Blast Wheel Stations cleans the strips from both sides in single pass. The strip is pulled by Coiler and other equipment and adjustable as per requirement. Maximum Coil Strip is of 60m per minute can be achieved. The entire operation of machine is meticulously controlled by PLC.

The strip is fed from de-coiler to inward side of tunnel /vestibule of pinch rollers of shot blasting machine. Then the strip enters into blasting chamber for blasting operation/purpose.8 blast wheel stations are located strategically on to blasting cabinet.(4 wheels are located on top of blasting cabinet and 4 wheels are located on to bottom portion of blasting cabinet) .the blasted /cleaned strip moves forward and enter into out let tunnel/ vestibule. From there strip is pulled by coiler and other equipment (arranged by customer).The machine is designed for cleaning strip 60m per minutes.

The Blast Cabinet is fabricated from 12mm thick heavy-duty prime quality steel plates, supported by strong rolled structure welded construction and engineered suitably for strength and rigidity to guarantee the optimum sturdiness. This robust rolled structure with thick plate foundation holds stand the machine and helps to reduce vibration keep within permissible limits. The Blast cabinet bottom is provided with mild steel perforated floor for protection against abrasion wear. The Vestibules are fabricated with 6mm thick sheet. The entire cabinet is lined with 10mm MnS.

The machine entails robust and sturdy Blast Cabinet on which 8 Blast Wheel Station are located at de-scaling angle. The cabinet is also equipped with Abrasive Recovery & Cleaning System and Dust Collector for ventilating Blast Cabinet. The strip is fed from de coiler to inward side of tunnel through pinch roller of Shot Blasting Machine. The strips enters into Blasting Chamber for Blast cleaning application. 8 Blast Wheel Stations cleans the strips from both sides in single pass. The strip is pulled by Coiler and other equipment and adjustable as per requirement. Maximum Coil Strip is of 60m per minute can be achieved. The entire operation of machine is meticulously controlled by PLC.

中文版

中文版