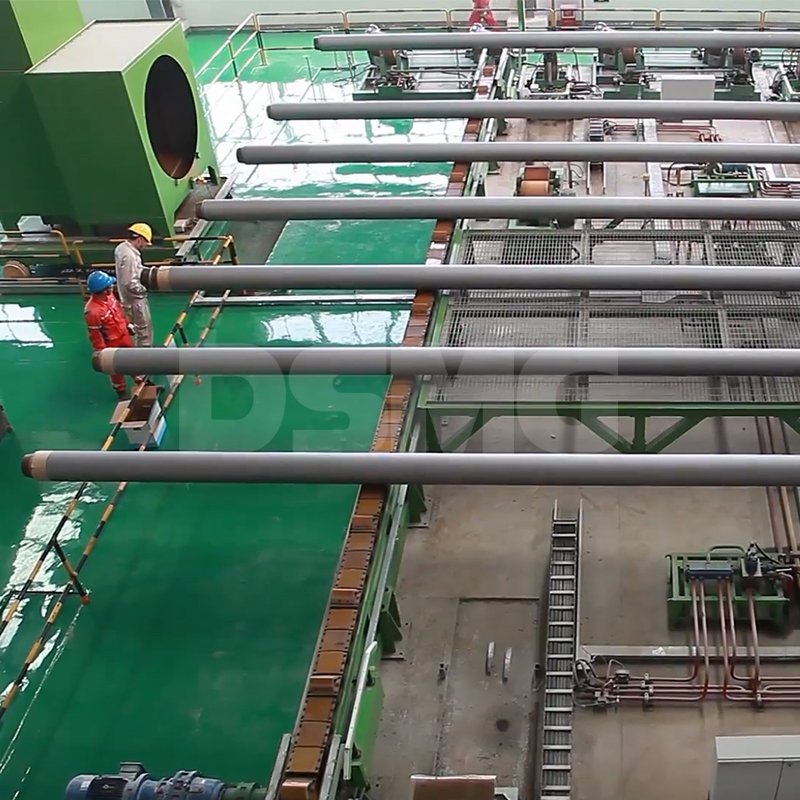

The steel plate pretreatment line refers to the processing technology in which steel is shot blasted to remove rust on its surface and coated with a layer of protective primer before processing. Through pretreatment, the corrosion resistance of mechanical products and metal components can be improved, the fatigue resistance performance of steel plates can be enhanced, and their service life can be prolonged. Meanwhile, it can also optimize the manufacturing state of the steel surface, which is conducive to the blanking of the CNC cutting machine and precision blanking. In addition, as the shape of steel is relatively regular before processing, it is beneficial for mechanical rust removal and automatic painting. Therefore, the adoption of steel pretreatment can greatly improve the efficiency of the cleaning work, reduce the labor intensity of the cleaning work and the pollution to the environment.

On the steel plate pretreatment line, computer monitoring, the simulation screen of the monitoring center, closed-circuit television monitoring are adopted, and the automatic coding instrument and automatic barcode printing device can be configured according to the requirements of users.

中文版

中文版