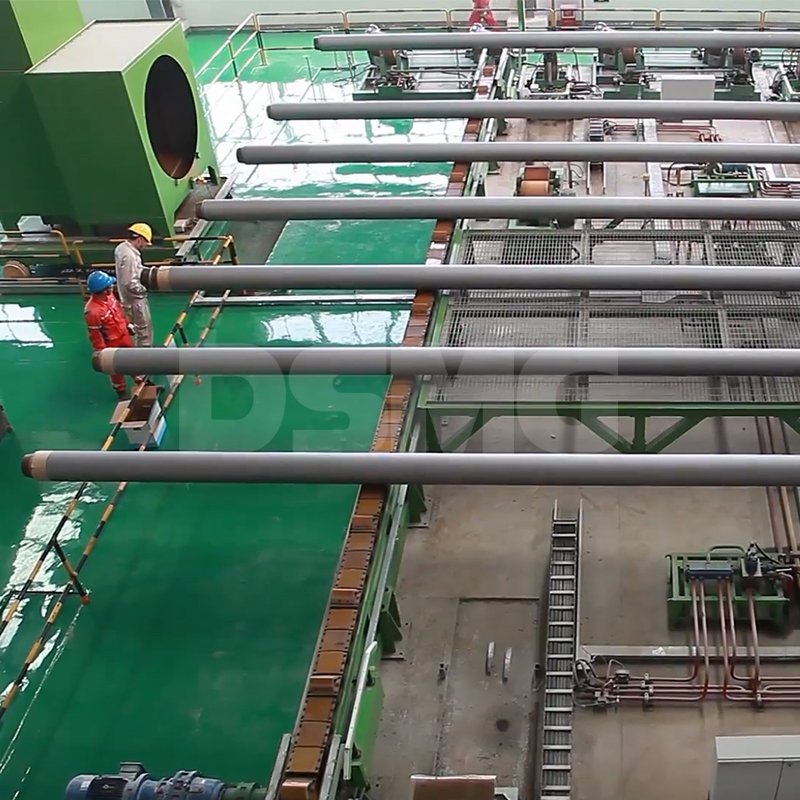

The steel pipe inner wall shot blasting machine is specifically designed for cleaning and strengthening the inner surfaces of steel pipes. It combines high efficiency and multifunctionality, meeting the processing demands of large-diameter pipes. Leveraging hydraulic motor drive technology, it achieves high-speed removal of residues (e.g., rust layers, oxides, contaminants) on the inner walls, significantly improving surface smoothness.

1. Equipment Structure and Technical Configuration

The extensible arm of the machine is constructed with high-manganese steel plates for enhanced durability.

The hydraulic motor drives the blast wheel, and the machine integrates German-imported components, including a hydraulic power unit, motor, and PLC fully automatic frequency conversion control system.

2. Automatic Cleaning Process and Effects

The machine employs automated shot blasting technology to eliminate surface rust. High-speed abrasive flow, propelled by efficient blast wheels, impacts and removes oxides, rust, and contaminants from the pipe's inner surfaces. This process produces a clean, glossy finish, improves the workpiece's tensile and compressive strength, and enhances paint adhesion. These outcomes collectively prevent corrosion, protect pipelines, and extend service life.

3. The Surface Quality of Workpieces

The cleaned surfaces achieve industry-standard smoothness and roughness levels (e.g., SA2.5–SA3).

4. Automated Loading, Unloading and Sealing System

An automatic pneumatic loading/unloading system is installed on the conveying trolley, enabling dual-side material handling.

After placing the workpiece, a mobile sealing chamber (driven by a reducer) moves toward a fixed sealing chamber, effectively sealing both ends of the pipe.

5. Abrasive Recycling and Dust Removal Process

During operation, the abrasive recovery system utilizes pneumatic conveying.

Supported by a dust collection system and negative pressure within the pipe, abrasive materials are transported to a recovery sub-chamber.

As the sub-chamber expands, the pneumatic force dissipates, and abrasives fall onto a belt conveyor for reuse.

中文版

中文版