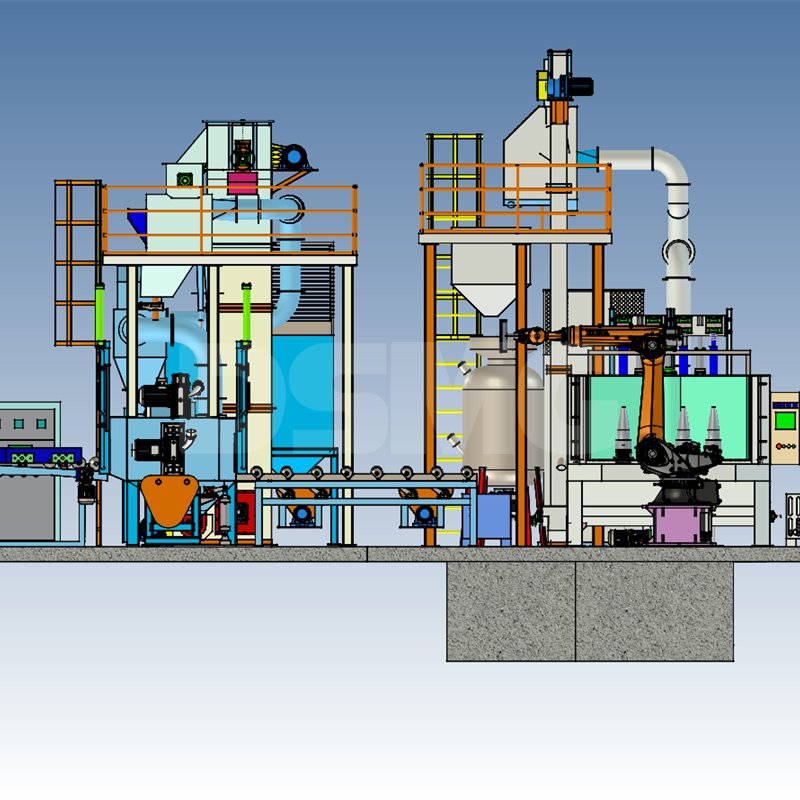

Compared to chemical methods for paint removal, sandblasting offers an eco-friendly solution. This technique efficiently strips coatings by projecting high-pressure abrasives onto surfaces. DISA Sandblasting Chambers provide a safe, contaminant-free working environment for industrial blasting operations. Our facilities are customized to meet your project specifications.

Sturdy Framework

Pre-cut wall panels and bolt-fastened assembly eliminate installation complexity while ensuring enhanced structural stability.

High-Quality Lighting

Equipped with ETL-certified 120cm six-lamp fluorescent lighting systems, protected by impact-resistant polycarbonate covers.

Safety Measures

Blast shields on intake/exhaust vents prevent abrasive leakage. Door limit switches automatically cut off air supply when chamber doors open.

Sturdy Framework

Pre-cut wall panels and bolt-fastened assembly eliminate installation complexity while ensuring enhanced structural stability.

High-Quality Lighting

Equipped with ETL-certified 120cm six-lamp fluorescent lighting systems, protected by impact-resistant polycarbonate covers.

Safety Measures

Blast shields on intake/exhaust vents prevent abrasive leakage. Door limit switches automatically cut off air supply when chamber doors open.

中文版

中文版