For products like gas cylinders, fire extinguishers, diving cylinders and cartridge cases, the inner walls thereof often require shot peening treatment in order to mitigate the internal surface stress and prolong their service life.

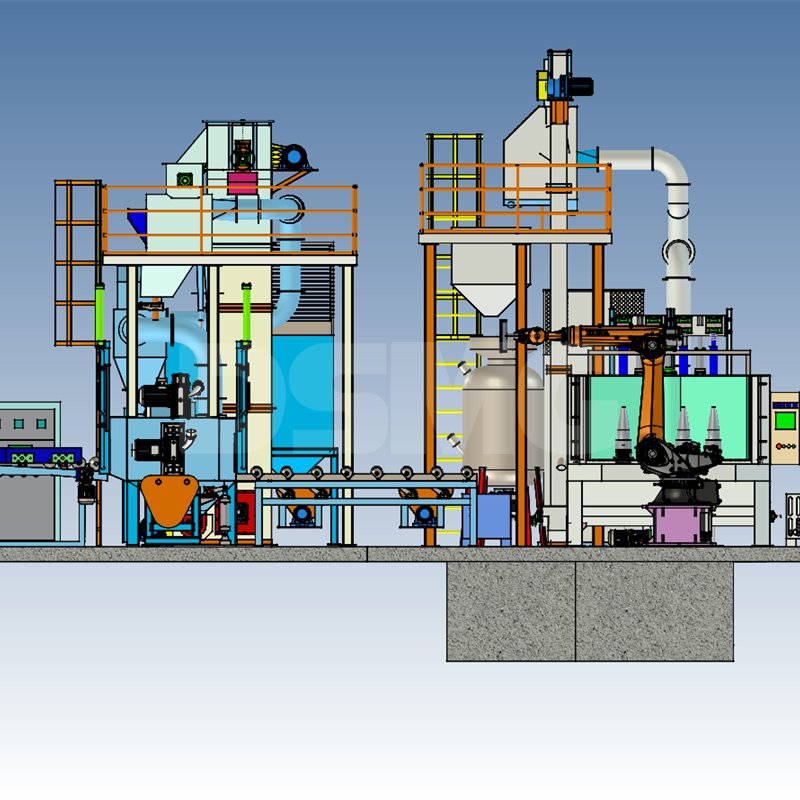

The interior shot peening equipment can be manipulated by a robotic arm. At the front end of the loading section of the equipment, a workpiece positioning device is designed. Through the positioning mechanism of the workpiece, its position can be precisely determined. Subsequently, the automatic detection mechanism and pneumatic gripper of the robotic arm will automatically seize the workpiece and transport it to the workpiece rotation station. Installed on the belt conveyor mechanism is a workpiece positioning groove, and the spacing between these positioning grooves is designed in such a way that it can be conveniently and reliably measured and controlled, which is consistent with the spacing between the workpiece rotation stations.

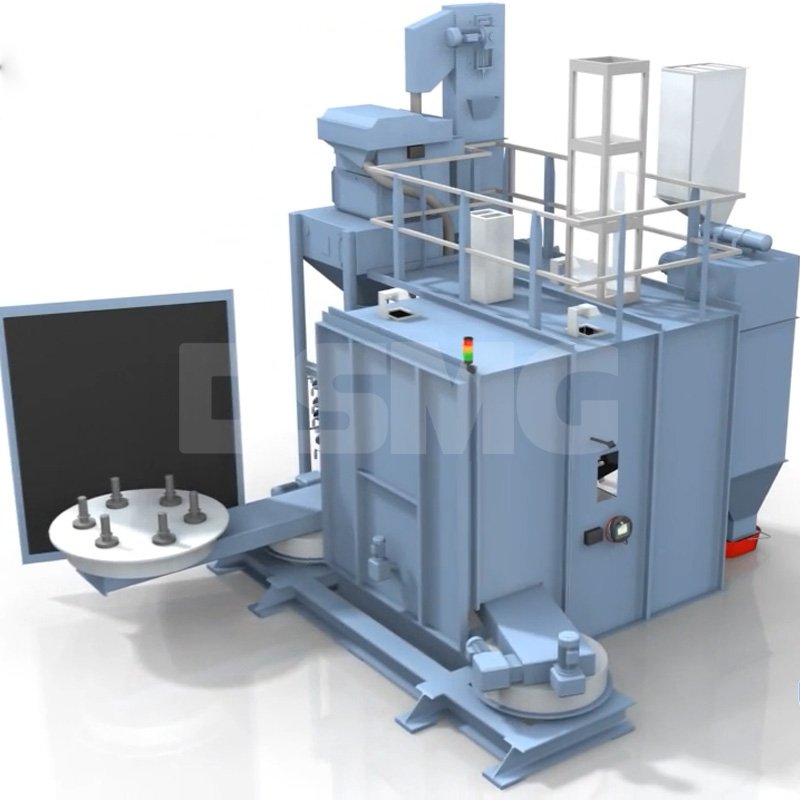

The interior wall shotblasting equipment is furnished with two turntables that operate in an alternating manner. The robotic arm can grasp two workpieces at a time and place four workpieces onto the turntables in two separate operations. Once placed, the products will be clamped firmly. Driven by the rotation mechanism, the turntables will start to rotate automatically. Meanwhile, the pressing mechanism will automatically apply pressure to the workpieces, and the inner wall spray guns will ascend and descend automatically to conduct the cleaning process on the workpieces. When the products on one turntable are undergoing processing inside the machine, the other turntable can be used for loading or unloading operations outside the machine. In this way, four cartridge cases can be cleaned simultaneously, and the cleaning time can be set as desired. After the cleaning is completed, the turntable inside the machine will rotate out, while the external turntable will rotate into the enclosed cleaning station, thereby ensuring the seamless and continuous progression of the processing flow. Moreover, the rotation speed of the turntables and the sandblasting speed are synchronized to perfection.

Shot peening for interior wall can also be realized by adopting the rotating spray gun approach.

The interior wall shotblasting equipment is furnished with two turntables that operate in an alternating manner. The robotic arm can grasp two workpieces at a time and place four workpieces onto the turntables in two separate operations. Once placed, the products will be clamped firmly. Driven by the rotation mechanism, the turntables will start to rotate automatically. Meanwhile, the pressing mechanism will automatically apply pressure to the workpieces, and the inner wall spray guns will ascend and descend automatically to conduct the cleaning process on the workpieces. When the products on one turntable are undergoing processing inside the machine, the other turntable can be used for loading or unloading operations outside the machine. In this way, four cartridge cases can be cleaned simultaneously, and the cleaning time can be set as desired. After the cleaning is completed, the turntable inside the machine will rotate out, while the external turntable will rotate into the enclosed cleaning station, thereby ensuring the seamless and continuous progression of the processing flow. Moreover, the rotation speed of the turntables and the sandblasting speed are synchronized to perfection.

Shot peening for interior wall can also be realized by adopting the rotating spray gun approach.

中文版

中文版