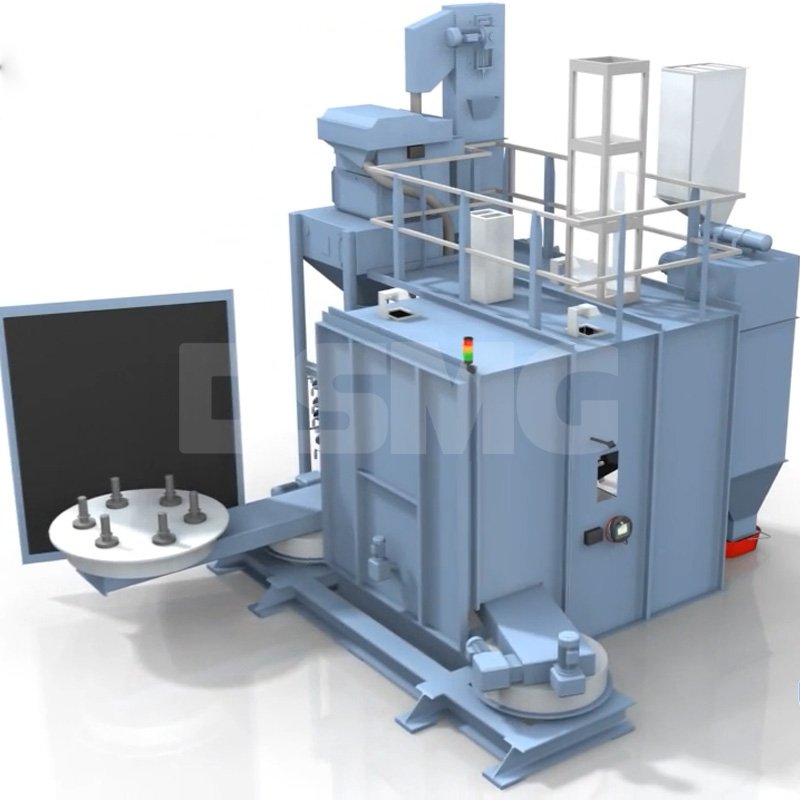

The whole set of equipment includes loading clamps, shot blasting chambers,steel pipe translation and rotation mechanisms, unloading clamps.

Precise servo control is achieved through shot blasting nozzles,as well as a complete shot recovery and filtration unit system with pressure shot blasting forks.

The steel pipes are loaded into position by the loading clamps.

Once in position, the operator selects the type of steel pipe on the intelligent operation panel and starts the program.The length and diameter of the steel pipes will be detected and verified by sensors,so no errors are allowed.Once confirmed to be correct, the steel pipes will be automatically loaded into the shot blasting chamber,two at a time. The steel pipes are lifted to the designated position and start to rotate.The shot blasting will be initiated according to the preset parameters.

The nozzles are precisely manipulated inside the steel pipes by a servo-driven trolley located outside the track.

Once the shot blasting is completed, the steel pipes are lowered and automatically unloaded onto the discharge ramp, ready for the next process.

The equipment is equipped with a closed-loop shot recovery and recycling system. All shots will be collected and cleaned before being returned to the shot blasting system.

A powerful centralized filtration and ventilation device is connected to the shot blasting chamber and the air separation unit.

Through the intelligent panel mileage system, engineers can use the touch screen to set process formulas and parameters,

such as the rotation speed of the steel pipe, the speed of the translational movement, the shot blasting pressure, the blowing pressure, and so on.

All alarms and prompts will be displayed on the screen, accompanied by trouble shoting pop-up windows.

Only through comprehensive control of parameters, a perfect shot recovery and recycling system, and systematic safety control of the key parts of the machine,

can the quality of the internal shot blasting treatment process be ensured to be consistent and without human intervention.

With long-term experience in customized shot blasting treatment solutions,we can achieve automation in this process and raise customer satisfaction to the highest level.

中文版

中文版