A space, three nozzles and an optimized loading system ensure the continuity of the process.

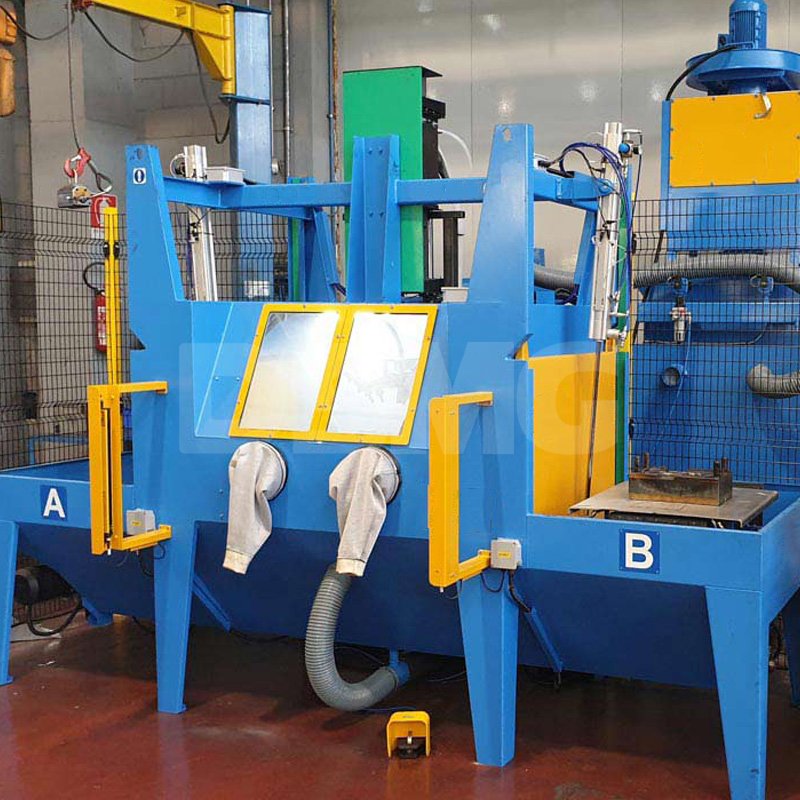

External and Internal Shot Blasting and Peening Machine

Disa has developed a fully automatic shot peening machine for transmission shafts, with the main purpose of cleaning the inner and outer surfaces of the transmission shafts. The equipment includes a six-axis robot equipped with two nozzles. This equipment is suitable for transmission shaft products of different sizes and shapes.

The design of the sandblasting chamber is very sturdy and durable, surrounded by hard baffles, steel plates and protective rubber to extend the service life of the machine.

A turntable is installed inside the machine, and the equipment is equipped with two positioning worktables. In this way, when one product is being processed in the machine, the next object can be prepared on the positioning worktable outside the machine. This creates an almost non-stop process with high productivity and low costs. It is also adjustable to make it easier to load and unload workpieces.

Two operating arms are set up to achieve uniform sandblasting on the inner and outer surfaces of the workpiece.

The first operating arm has two spray guns and can move in two axial directions, so that you can sandblast the outside according to the shape of the workpiece.

The second operating arm has only one sandblasting nozzle, which is used for sandblasting the inside and can move in one axial direction.

An additional manual spray gun is used for manual sandblasting and is operated by a pedal at the bottom.

The shot peening media can be used efficiently and effectively because they can be fully automatically recovered and classified. The sandblasting process requires appropriate filtration of the sandblasting media. When the sandblasting cycle is turned on, all the sandblasting media will be collected in the vacuum cleaner below the sandblasting chamber and then sucked into the filtration system through polyurethane pipes.

The sandblasting media will pass through a cyclone separator, where dust will be separated from the media and then collected into a dust collection container. Other particles falling from the cyclone separator will be separated by a vibrating screen.

The vibrating screen has two different screens. Those screens will screen out all particles that are too large or too small to be used further.

中文版

中文版