Inner Surface Shot Blasting Machine for Boilers

The shot peening machine for the inner tank of the water heater is used for surface treatment before spraying coatings. It can enable the coatings to adhere well to the inner walls of the water heater. By adopting the internal sandblasting solution, it has successfully replaced the environmentally unfriendly process of chemical surface pretreatment. It removes all oxides and foreign substances on the surface and prepares a proper surface texture for the application of thermal spraying coatings.

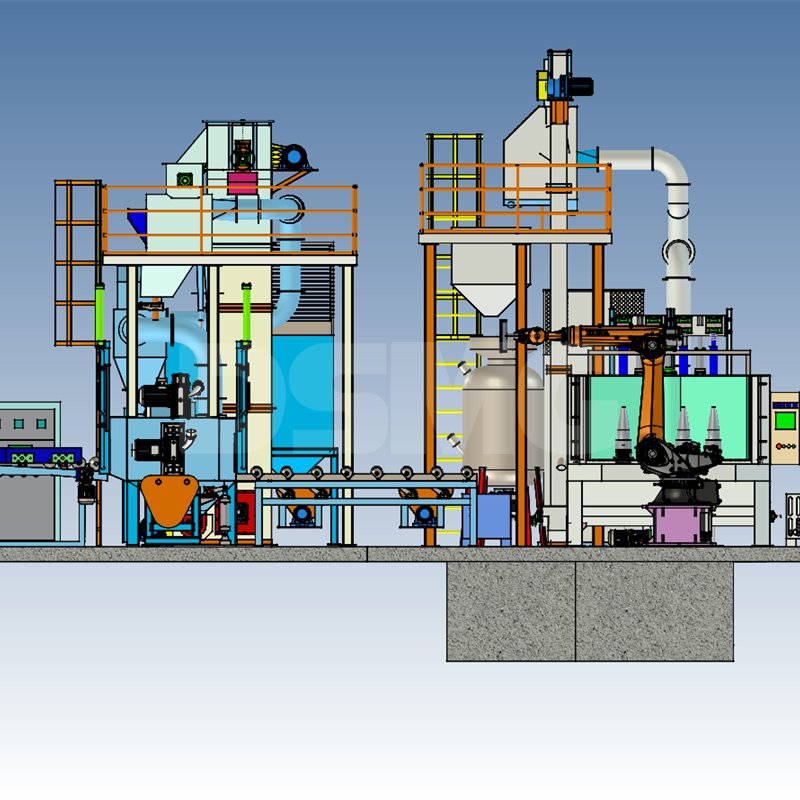

The shot peening machine for the inner tank of the water heater operates in synchronous working cycles within the complete production process. Components are suspended and transported by our overhead conveyor, and they come in different sizes and diameters. This machine consists of three main stations, and pairs of boilers will pass through each station in sequence to conduct different sandblasting operations inside the boilers.

This machine is equipped with a panel management system. The visual design on the large touch screen and the user-friendly menus enable operators to use, control and maintain the machine with ease.

The precise clamping system can ensure that the boilers are in a controlled position and also enables a controllable rotational speed when the components are undergoing sandblasting operations. Specially designed sandblasting nozzles are fixed on the vertical operating device.

This machine is equipped with an automatic closed-loop recycling system. The generated waste materials will be collected at the bottom of the cabinet and then transported by a full-length screw conveyor. The bucket elevator transports the materials through an air-line separation device, where dust is separated from the medium. Only qualified media will be filled into the silo above the pressure sandblasting generator and put into use again through multiple outlets.

The sandblasting cabinet is equipped with multiple dust suction points, which are connected to a powerful centralized filtering unit. This recycling system ensures repeatability, quality as well as cost reduction.

中文版

中文版