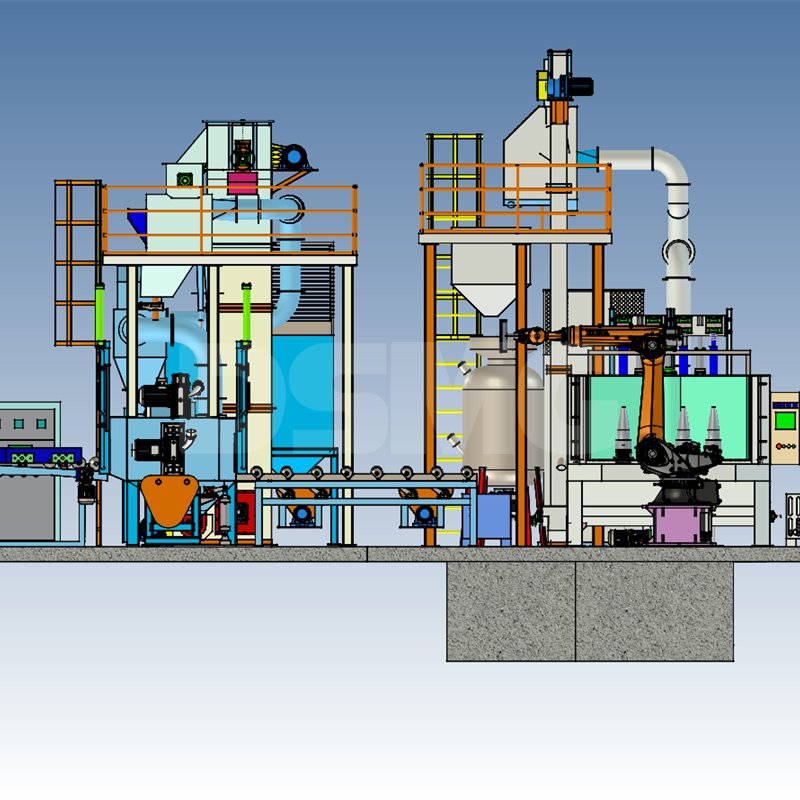

The automatic internal sandblasting booth is composed of multiple key components. The workpiece conveying and rotating mechanism guarantees smooth and precise transportation and rotation of workpieces, allowing for all-round exposure to the sandblasting process. The spray gun combined with its lifting and traversing mechanism can flexibly adjust its position to reach different areas of the parts for optimal blasting results. The electromagnetic flow valve precisely controls the flow of abrasive materials, enhancing the accuracy and stability of the sandblasting operation. The shot recovery, circulation and sorting mechanism not only recycles the abrasive media effectively but also sorts them to maintain their quality, which greatly reduces waste and operating costs. The air source and compressed air treatment system provides a stable and clean air supply, ensuring the consistency and high quality of the sandblasting effect. Moreover, the automatic charging sandblaster enables continuous operation without frequent manual intervention, and the electrical system coordinates all these components to ensure seamless and intelligent automation. Altogether, these features make the automatic internal sandblasting booth an ideal choice for processing high-value parts with high precision and efficiency.

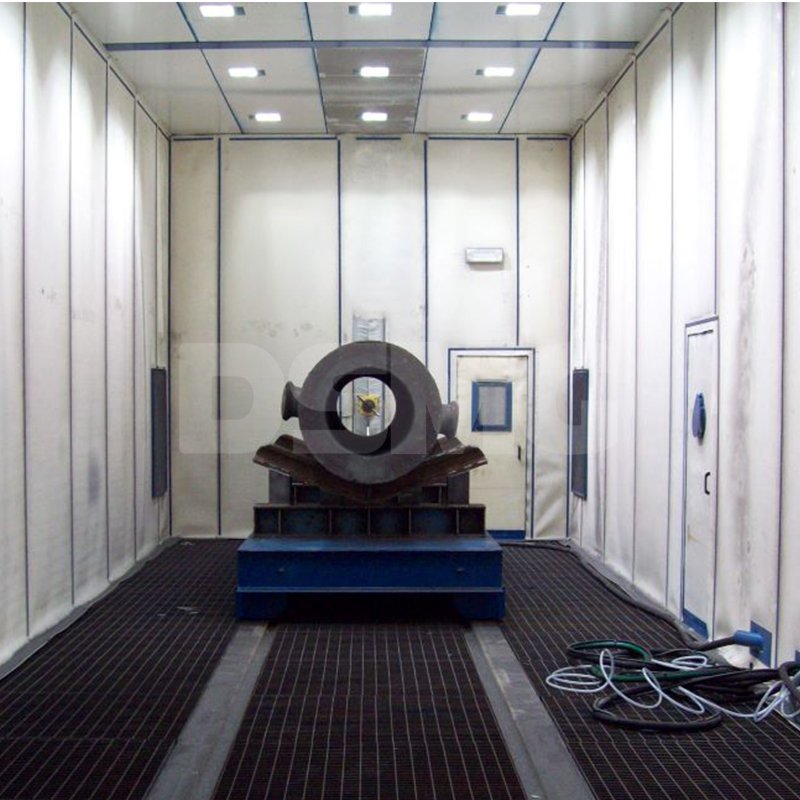

Workpieces are conveyed via a rotary trolley. It transports them in and out of the sandblasting booth and enables rotation for sandblasting. With positioning, limit stops, and angle memory. T-shaped grooves on the trolley help fix workpieces, The connecting rod can clamp the workpiece's exterior horizontally for sandblasting or be placed vertically to handle its inner holes.

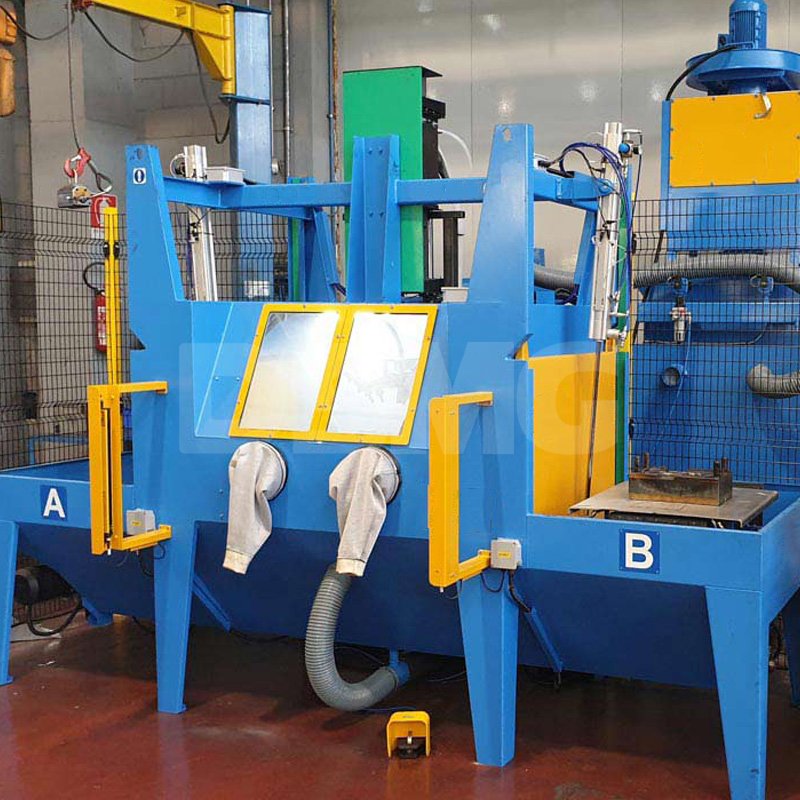

The abrasive is sorted using a rotary vibrating screen and a roller screen. The roller screen separates and removes deformed shots. Given different workpieces and specific process requirements, S230 and S390 steel shots are used. A three-dimensional vibrating screening machine ensures accurate screening. In the rotary vibrating screen, the first and bottom layers are waste, the second layer is S390 steel shots, and the third layer is S230 steel shots. Two roller screens are added to ensure shot roundness, excluding angled and deformed ones.

The abrasive flow in the sandblasting booth equipment is digitally controlled by an electromagnetic flow valve. Five sets of MagnaValve valves and EC-24 controllers are chosen. Each spray gun has a MagnaValve electromagnetic flow valve for automatic shot supply control, keeping the injection amount error within 5% and ensuring the stability of the workpiece sandblasting strengthening process.

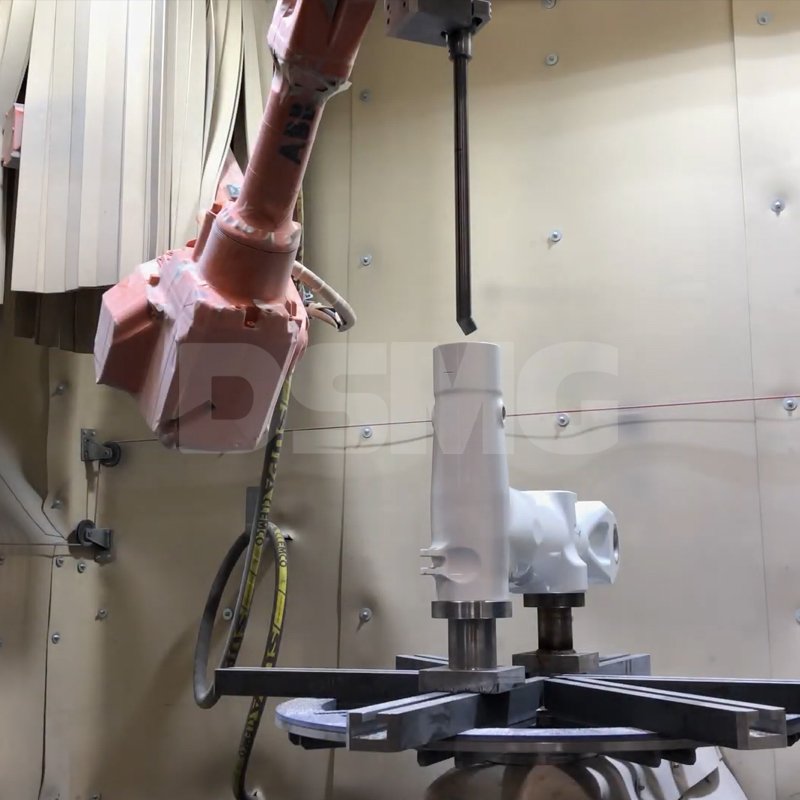

To keep the sandblasting stable and continuous, an automatic charging sandblasting pot is used. There are five peening guns in total. Four combined spray guns rotate simultaneously with positioning, rising from the zero position to the end position. Their nozzles are curved to spray the workpiece's inner holes. These shot peening guns can move in the lifting and horizontal directions. The power for the peening gun lifting and traveling trolley comes from an electric push rod with reliable performance. The lifting and traveling use a V-shaped wheel structure to prevent steel shots from piling up on the guide rail and affecting performance. One independent peening gun works on the workpiece's exterior, moving horizontally to shot peening its outer surface.

The abrasive is sorted using a rotary vibrating screen and a roller screen. The roller screen separates and removes deformed shots. Given different workpieces and specific process requirements, S230 and S390 steel shots are used. A three-dimensional vibrating screening machine ensures accurate screening. In the rotary vibrating screen, the first and bottom layers are waste, the second layer is S390 steel shots, and the third layer is S230 steel shots. Two roller screens are added to ensure shot roundness, excluding angled and deformed ones.

The abrasive flow in the sandblasting booth equipment is digitally controlled by an electromagnetic flow valve. Five sets of MagnaValve valves and EC-24 controllers are chosen. Each spray gun has a MagnaValve electromagnetic flow valve for automatic shot supply control, keeping the injection amount error within 5% and ensuring the stability of the workpiece sandblasting strengthening process.

To keep the sandblasting stable and continuous, an automatic charging sandblasting pot is used. There are five peening guns in total. Four combined spray guns rotate simultaneously with positioning, rising from the zero position to the end position. Their nozzles are curved to spray the workpiece's inner holes. These shot peening guns can move in the lifting and horizontal directions. The power for the peening gun lifting and traveling trolley comes from an electric push rod with reliable performance. The lifting and traveling use a V-shaped wheel structure to prevent steel shots from piling up on the guide rail and affecting performance. One independent peening gun works on the workpiece's exterior, moving horizontally to shot peening its outer surface.

中文版

中文版