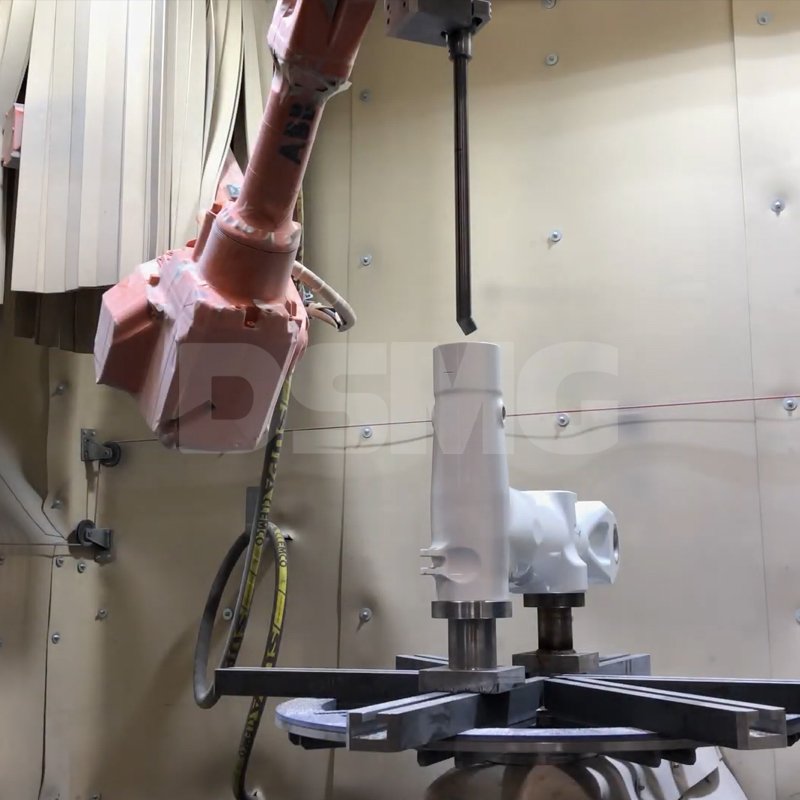

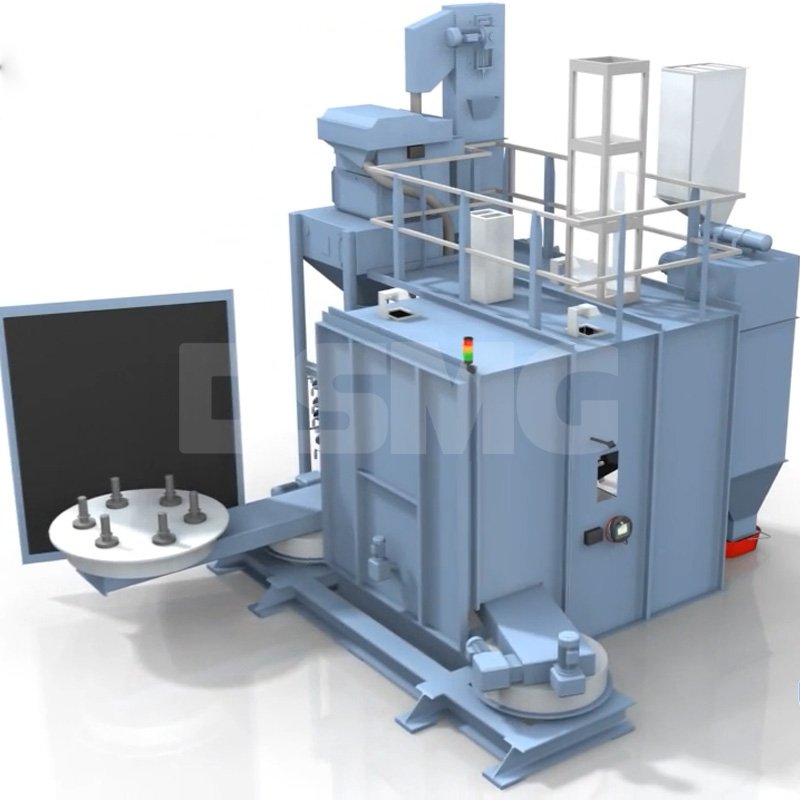

The front panel of the sandblasting machine is equipped with a safety glass observation window, protected by a fine mesh cover and with a built - in fluorescent lamp. The manual loading door is on the left side. Inside the sandblasting cabinet of this sandblasting system, there is a powered turntable. Two robotic arms are equipped with four sandblasting guns, and the vertical movement of the guns is pneumatically operated.

The abrasive falls into the hopper from the sand blasting cabinet by gravity and is recycled to the silo through a bucket elevator. The silo includes a vibrating separator screen and a double - tank continuous sandblasting system.

The workpiece is installed on the fixture of the rotating turntable. The workpiece cart can be pushed and pulled for easy loading and unloading. The bottom of the workpiece cart is equipped with a rotary drive motor to power the turntable, and the speed - regulating knob is installed on the control panel.

Four nozzles are connected to two robotic arms, with two nozzles on the rear side and two on the side of the workpiece. The interior of all nozzles is made of tungsten carbide, and they use threaded joints for easy replacement of hoses or nozzles.

中文版

中文版