Inside Blasting Machine for Engine Blocks

The engine blocks shot blasting machine is a device that uses steel shot to clean the water and oil passages inside the engine block. It is a fully automatic system, and all you need to do is to place the block correctly at the loading station. The sandblasting chamber is equipped with 12 nozzles and a blowing station. The engine block is conveyed inside the machine through a chain conveyor system. Once the workpiece to be detected is present, the nozzles in the sandblasting chamber will be close to the block to carry out sandblasting treatment on the target area. The sandblasting chamber body is made of 12mm thick steel plates and lined with high manganese steel protective plates, featuring high wear resistance and impact resistance.

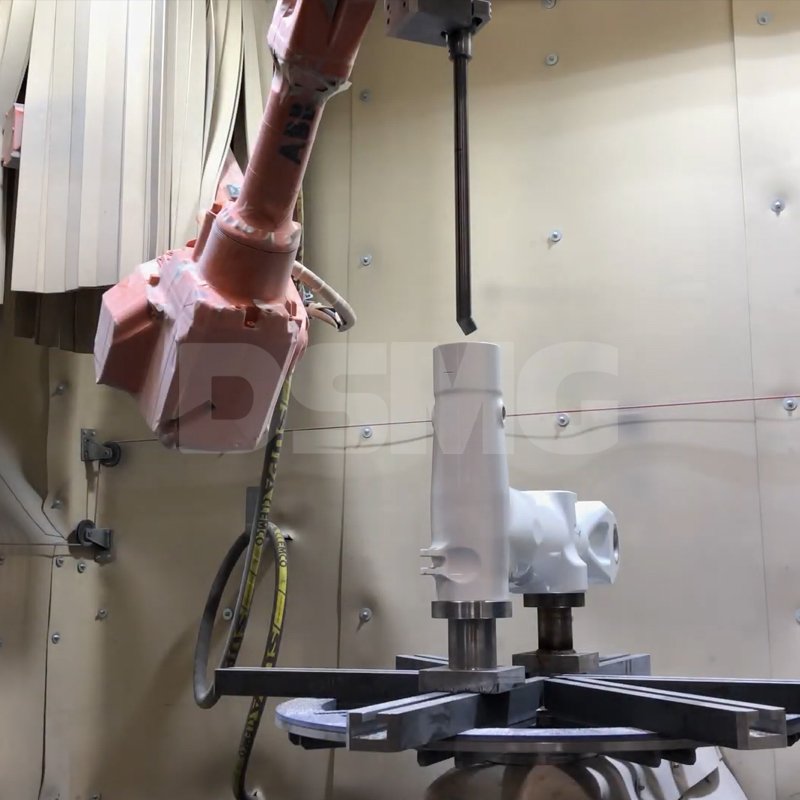

The Automated Engine Head Shot Peening Machine adopts advanced automation technology and can precisely perform shot peening treatment on engine heads. This system operates completely independently and is aimed at shot - peening the cylindrical areas of engine heads.

Features:

Features:

The abrasive is recovered from the cabinet through a pneumatic conveying system.The dust collector is equipped with a high-power blower for sucking the abrasive and dust out of the cabinet.

The dust and fine powder are removed through a cyclone separator. The reusable abrasive is finely screened by a vibrating screen to make its size meet the requirements.

The automatic shot adding device can replace the broken steel shots screened out by the sieve. The system includes a warning function for low abrasive level.

The dual pressure tank configuration enables uninterrupted sandblasting operations during the refilling of the pressure tanks.

There are two sets of pressure tanks, with each set having 6 abrasive outlets, which can supply materials to 6 pressure sandblasting nozzles.

Tungsten carbide sandblasting nozzles are used, featuring high wear resistance.

中文版

中文版