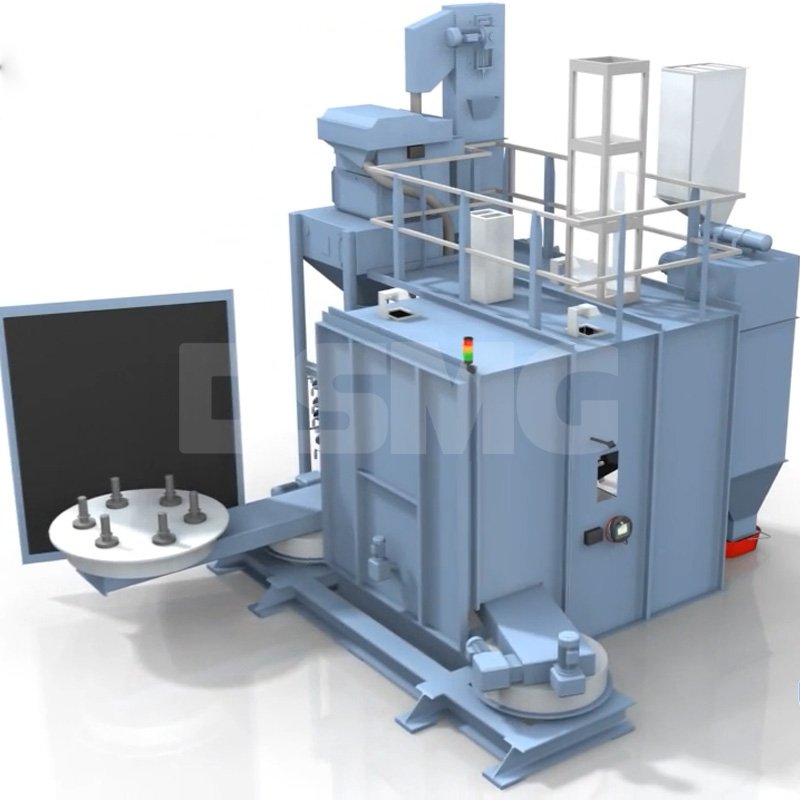

The shot peening machine with a rotary worktable provides precise shot peening treatment for complex parts. This type of automation is suitable for parts that require mass production and repeated processing, such as gears, sprockets and other similar part types. The multiple stations enable automatic loading and unloading of parts while the shot peening operation is being carried out at the rear of the cabinet, thus maximizing the production output. The satellite turntable sandblasting system can accurately position the workpiece in front of the sandblasting nozzle, ensuring the repeatability required by the process.

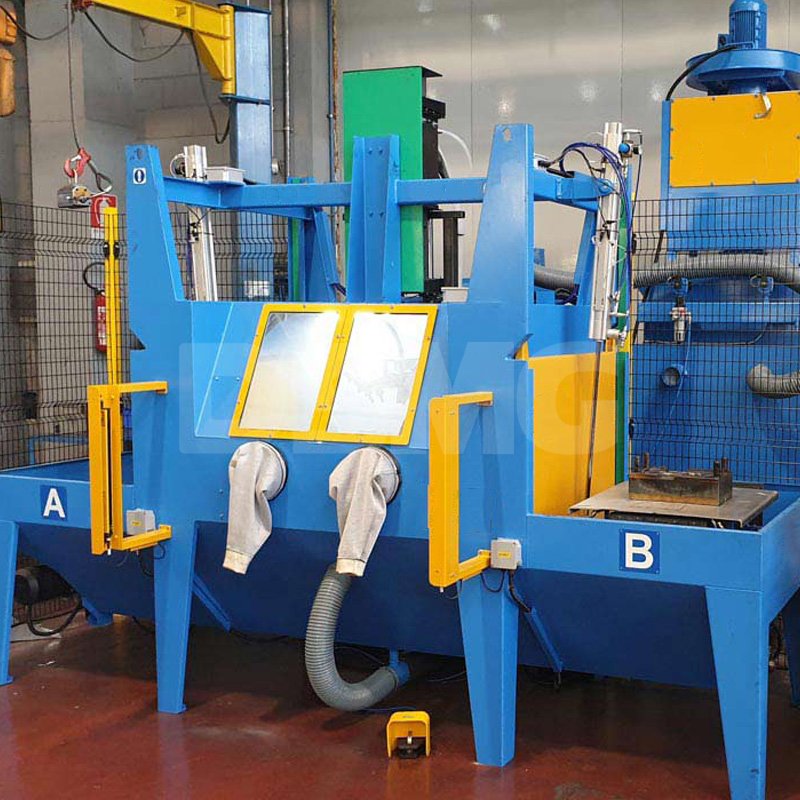

The sandblasting chamber is made of 12mm thick steel weldments. All components are lined. A 25mm thick polyurethane lining is used for wear protection, and a 50mm thick foam is used for sound insulation. The maximum noise level is 85 decibels.

It is equipped with boron carbide suction sandblasting guns with a diameter of 10mm, which can be individually adjusted and controlled according to the customer's production requirements. The sandblasting gun rods, fixtures and locking bolts are all made of A2 steel (Rockwell hardness 62).

The number of sandblasting gun configurations can range from 6 to 12.

The indexing of the rotary workpiece station turntable is 60 degrees.

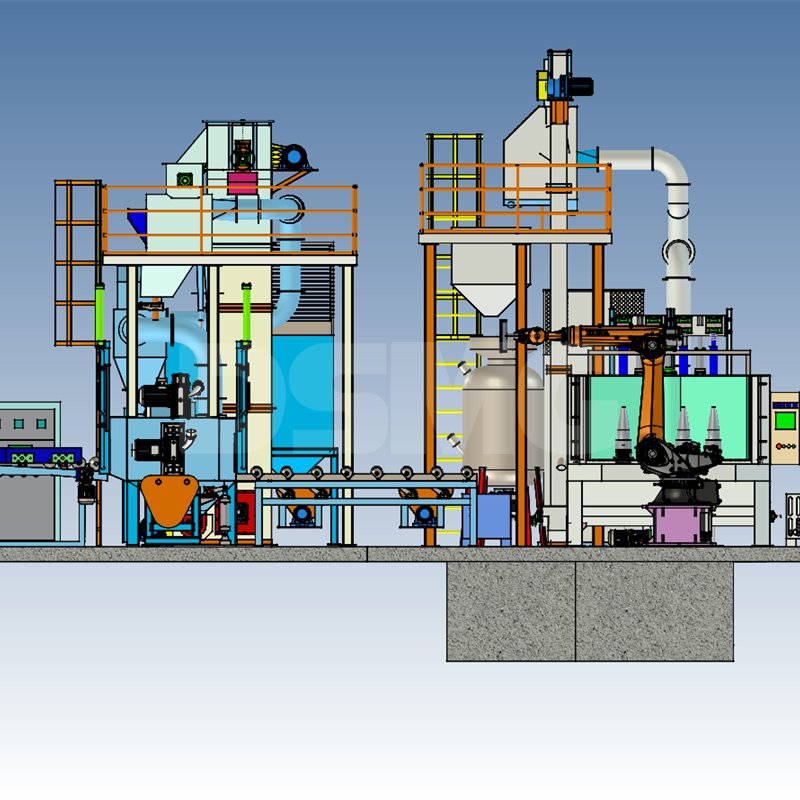

The sandblasting system is equipped with a dedicated dust collector to achieve the best abrasive recovery and ventilation of the sandblasting chamber.

The control panel has automated control. Safety features include infrared light curtains and workpiece loading buttons, and the design is easy to operate.

The customized rotary indexing shot peening machine uses either fixed or mobile sandblasting guns.

Flexible loading and unloading mechanisms.

Precision rotary fixtures at the shot peening stations.

Adjustable abrasive supply and air pressure.

Sealed blowing and cleaning stations.

Applications of the Rotary Indexing Shot Peening Machine

The rotary worktable shot peening equipment and the automatic shot blasting machine can be used to enhance the strength and extend the fatigue life of various metal parts, covering a wide range of components from gears, turbine blades / jet engine blades to drill bits and engine blocks:

Gears

Camshafts

Shafts

Turbine blades

Connecting rods

Engine blocks

中文版

中文版