Roller conveyor shot blasting machine is designed for cleaning steel plates and section bars and mainly used for descaling, rust removal, paint removal, coating preparation, deburring and surface preparation, such as welding, cutting, machining and burning operations.

The workpieces are moved through the shot blasting machine on roller conveyor. The blasting wheel is made of wear-resistant material and the power is from 7.5 kw to 15 kw, so that the blasting wheel can efficiently blast shots. You can make a choice among four basic types of roller conveyor shot blasting machines, namely DS04-06,DS04-10, DS04-12 and DS04-15.

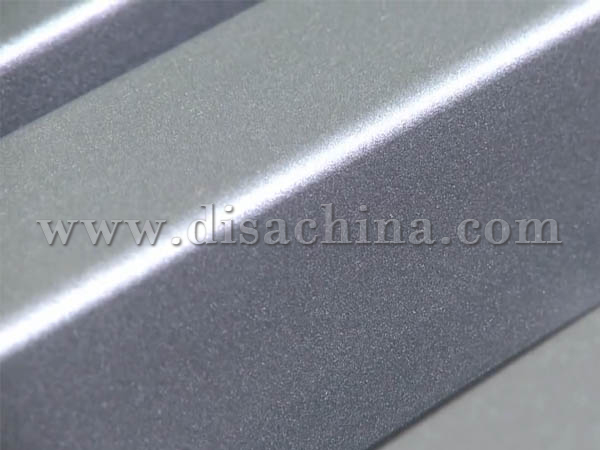

The housing of the roller conveyor shot blasting machine is protected by a wear-resistant shield that is made of manganese steel lining. The polyurethane sealing strip keeps the abrasives in the feeding room and the exit cleaning room. The rolling brush and the high-pressure fan remove the abrasives on the workpieces and the abrasives then go into the roller conveyor shot blasting machine. The reversing and continuous automatic cleaning of the abrasives can be realized through the spiral conveyor, the elevator and the separator.

The roller conveyor shot blasting machine has the following characteristics:

1.The roller conveyor shot blasting machine is designed and manufactured according to the requirement of users and can operate reliably and continuously and can improve the production efficiency.

2.A high-efficient blast wheel is adopted and is simple is structure and convenient to maintain.

3.Structural steel is welded with the steel plate to form the blasting chamber body and the blasting chamber body is reasonable in structure and is long in service life.

4.The wear-resistant plates of the blasting wheel and the blasting chamber are made of special wear-resistant material, reduces consumption and lowers cost for users.5.PLC electrical control can detect the faults of the abrasive controllable gate and abrasive conveying and can realize automatic controlling of the complete machine.

6.The dust collecting system adopts the most advanced pulse type back blowing dust collector in the world and meets the national environmental protection requirements.